CBSE Class 6 Science Notes Chapter 3 Fibre to Fabric

CBSE Class 6 Science Notes Chapter 3 Fibre to Fabric are given below. Our notes are designed by the subject experts and are as per the NCERT guidelines. These notes include all the important points of the chapter in detailed way, so you can refer to this whenever required. Study Path provides CBSE Class 6 Science Notes Chapter 3 that are easy to understand and also free downloadable PDF format, so students can practice it for their studies and get good marks in their examinations.

Fibre to Fabric Class 6 Notes Science Chapter 3

What are Fibres and Fabrics?

Fibres are the materials, which are available in the form of thin, continuous and flexible strands spun into yarn and made into fabrics.

Fabrics are defined as a cloth material made by knitting or weaving or of threads together.

Types of Fibre-

There are two types of fibres classified according to their origin.

Natural Fibres: Fibres that come from plants and animals i.e. are found in nature are called Natural Fibres. Examples:

- We get jute and cotton from plants.

- Wool is acquired from the fleece of a goat or sheep. It can also be acquired from the hair of yak, rabbits and camels.

- Silk fibre can be procured from the cocoon of silkworms.

Synthetic Fibres: Fibres that are made of chemical substances i.e. substances not found directly in nature are classified as synthetic fibres. Examples include nylon, acrylic and polyester.

Difference between Synthetic and Natural Fibres

| Natural Fibre | Synthetic Fibre |

| Natural fibrers are fibers that are found in nature. Ex: Woo, Silk and Cotton etc. | These fibres are man made or simply prepared in lab. Ex: Nylon, Teflon etc. |

| They are good absorbents and so able to absorb heat, temperature, cold, sweat etc. depending on conditions and nature of fibres. | They do not have such pores as they are made up of chemical and so do not act as good asorbents. |

| No spinning process is required for filament production. | Melting, wet or dry spinning processes are used for filament production. |

| Comfortable in use. | Not as comfortable as natural fibres. |

| Their length is naturally obtained and it is not possible to change the fibre structure. | Their lengths can be controlled by man and the fibres can easily be changed to different structures. |

Animal Fibres

Silk and wool are fibre obtained from animals.

Wool fibres come from sheep, camel, goat, and yak. The process involved in making animal fibres into wool follows a series of steps — Shearing, Scouring, Sorting, Cleaning, Dyeing, Straightening, Rolling and Combing.

Silk fibres are obtained from the silkworm and the process of obtaining silk from the silkworm is called sericulture. The silk thread or the yarn is obtained from the silk moth’s cocoon.

The life cycle of a silkworm begins from the:

Stage 1- After mating, female silk moth lays around 200 – 300 eggs at a time.

Stage 2- The egg hatches and new silkworms arise and feed on mulberry leaves for around 30 days and move into the next stage.

Stage 3-Cocoon, a protective layer or a silky web spun is developed around the larvae, which is the size of a small cotton ball made of a single silk thread.

Stage 4- Pupa stage. A stage where silk fibres is obtained by killing the pupa and plunging the cocoon into boiling water and unwind the silk thread.

Stage 5- The last stage of a life cycle, in which the completely developed pupa changes into an adult moth. Again the life cycle begins from here.

Plant Fibres

- Cotton, wool and jute are the fibres obtained from the plant source.

- Jute fibre is obtained from the stem of jute plants. It is soft, shiny and long fibre with a silky texture.

- Cultivated in rainy seasons and is basically grown in the states of West Bengal, Bihar and Assam.

Cotton

Where does cotton wool come from?

- Cotton plants are grown in fields usually at places having a warm climate and black soil.

- Some cotton producing Indian states are Punjab, Gujarat, Madhya Pradesh, Karnataka, Maharashtra etc.

- Cotton plants bear fruits the size of a lemon called Cotton Balls which burst open upon maturing and the seeds wrapped up in cotton fibre become visible. Cotton is generally picked by hand from these balls.

Ginning: Ginning of cotton can be defined as the process of separating cotton fibres from cotton seeds. Traditionally, ginning used to be done by hand but these days machines called double roller cotton ginning machines are widely in use.

In the above figure, we see a boy ginning by hand.

Jute

- Jute fibre is obtained from the stem of the plant.

- Unlike cotton, jute is cultivated in the rainy season.

- Some jute producing Indian states are Bihar, Assam and West Bengal.

- The plant is harvested during its flowering stage.

- The stems of these harvested plants are then soaked in water for four to five days

- The stems are left to rot and then the fibres are picked out by hand.

Yarn: Yarn is the spun thread that is made from fibres in order to produce a fabric.

Spinning Cotton Yarn

Spinning: Spinning is the process of constructing yarn from fibres in which fibres from a huge heap of cotton wool are taken out and twisted which brings them together to form a yarn.

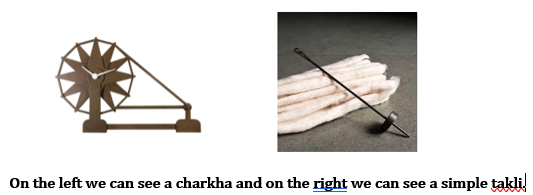

There are two major devices called Takli which is a hand spindle and Charkha which is also a hand-operated device, are used for spinning.

The spinning of yarn on a bigger scale is done using spinning machines following which these yarns are used to weave fabric.

Khadi was the term used to denote clothes which were made from homespun yarn.

On the left we can see a charkha and on the right we can see a simple takli.

Yarn to Fabric

There are two major ways using which yarn is converted to fabric, namely, Weaving and Knitting.

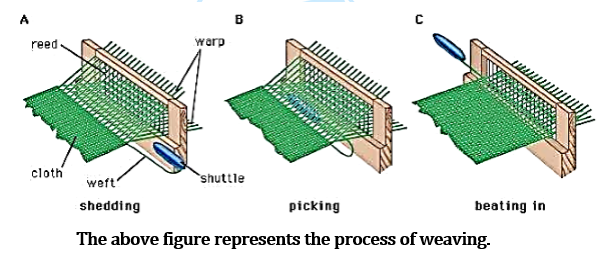

- Weaving: The process of entwining two sets of yarn simultaneously to make fabric is called Weaving. The process is done using a loom (which can either be operated by hand or by a machine) which interlaces two sets of yarn at right angles to each other.

- Knitting: Knitting is the process by which a single strand of yarn is used to make a piece of fabric. Socks, sweaters, mufflers and a lot of other winter clothes are made of knitted fabrics. Knitting can be done by hand as well as by machines.

History of Clothing Material

- In earlier times, when people did not have access or the knowledge to process fibre, big leaves and the bark of trees were used by people to cover themselves.

- After settlement began in agricultural communities, they learnt how to weave. They used grass and twigs to make mats and baskets. Animal hair or fleece and vines were warped together into stretched out strands which were then woven into fabrics.

- There was an abundant growth of cotton in areas near Ganga, which the early Indians readily used to make fabrics for themselves.

- There is another plant named flax which yields natural fibres.

- The early Egyptians cultivated both cotton and flax and used them for creating fabrics. These plants grew near the river Nile.

- But in those days, people were not aware of the process of stitching. They simply used to wrap around the fabric around different parts of their bodies. Even today unstitched clothes like sarees, dhotis, lungis or turbans are widely in use.

- It was with the advent of the sewing needle that people learnt how to stitch fibres to make fabric.

Revision Notes for CBSE Class 6 Science Chapter 3 – Free PDF Download

Our Class 6 Revision Notes will provide a quick glimpse of the chapter and improve the learning experience. We have made these revision notes keeping the convenience of students in mind so that it proves more effective. You can easily read these Class 6 notes just by clicking on the chapter names provided above.